Recently, the 820 steel pipe hydrostatic tester was successfully completed on the first attempt. This machine is specifically designed to perform water pressure tests on welded pipes, ensuring that the steel pipes meet quality standards by det...

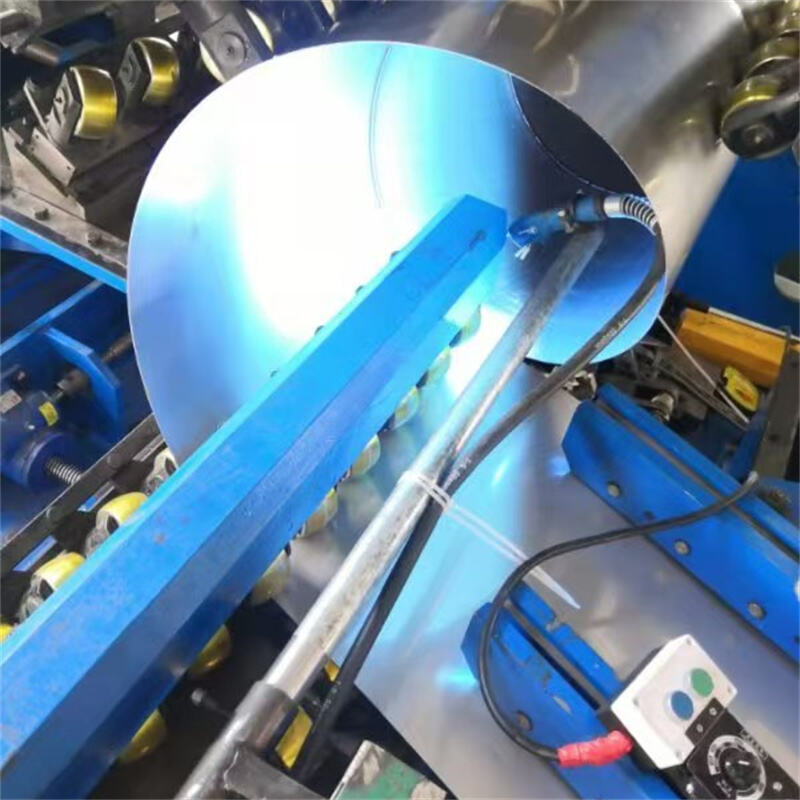

This Φ820mm Spiral Welded Pipe Milll has been successfully commissioned—and during its very first trial run, the mill smoothly produced pipes. This milestone underscores the equipment’s exceptional efficiency and reliability. The pipe...

This 820 Steel Pipe End Facing and Beveling Machine has recently been successfully commissioned, laying a solid foundation for subsequent welding, connection, and other processes. The machine features a dual-head configuration, allowing for the...

The Jiangsu ultra-large-diameter 4220 spiral welded pipe mill has successfully completed commissioning and is now producing pipes. This machine employs a front-swing intermittent production method and represents a fully integrated, automated system c...

We are currently in the final stages of production for a 2540×20 spiral pipe mill at our factory, and the equipment will be completed in just 20 days! If you're interested, we invite you to place your order now! This is a limited o...

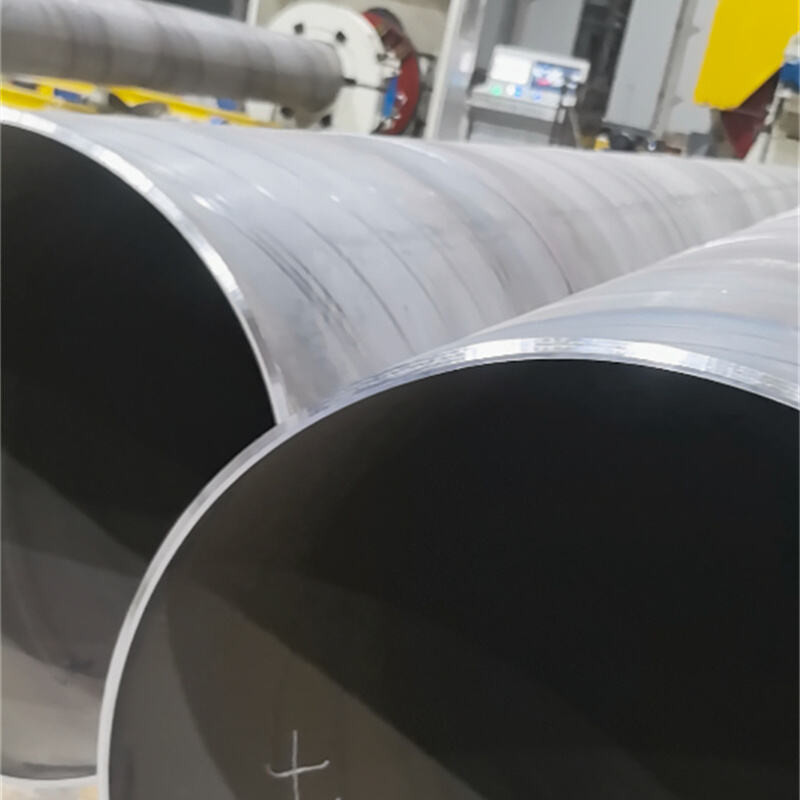

With the successful rollout of the first steel pipe, our newly installed 3620×30mm spiral welded pipe production line in Gansu has officially entered operation. Featuring advanced spiral forming technology combined with high-precision welding p...

This is an independently developed 1500×3mm stainless steel spiral welded pipe equipment ,specially designed for the efficient and precise production of thin-walled stainless steel pipes. The equipment supports continuous forming and ...

Automatic slag removing machine for steel pipes is one of the key equipment in the finishing section of the spiral pipe production line. It is used to remove the welding slag remaining inside the pipe during the submerged arc welding pipe manufacturi...

ONLINE

ONLINE